- Home |

- Case Studies

Case Studies

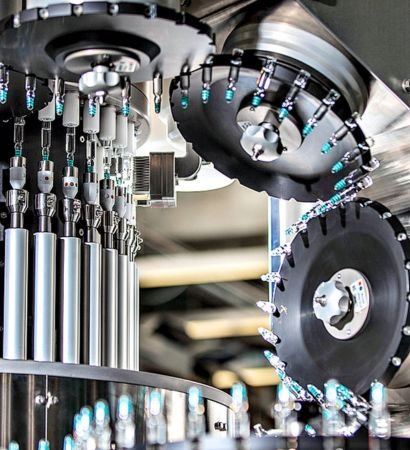

Industry : Pharmaceuticals

Barcode Printer and Label Applicator on Glass Test Tube

Problem Statement

- Manual Barcode Pasting

- No Record of Barcode

Solution Delivered

- Built Glass Test Tube Storage

- Built Roller Conveyor to Auto Move the Test Tubes

- Built Barcode Generator, Printer and Applicator

- Built SS Pharma Trade Tray for Tubes Collection

- Built Automatic Tray Stacking Unit

Productivity Increased by 40% | Process Time Reduced by 30% | Accuracy Increased to 99%

Industry : Pharmaceuticals

Robotic Pick & Place

Problem Statement

Manual Recording of Barcode

Manual Weighing and Record Keeping of Test Tubes

Solution Delivered

Built six Axis Robot

- Built Barcode Scanner

- Built High Accuracy Weighing Machine

- Developed SCADA for Operation Selection

- Built SS Pharma Grade Structure

Productivity Increased by 35% | Process Time Reduced by 40% | Accuracy Increased to 99%

Industry : Automobile

Automatic Online Vision Inspection & Packaging Machine for Wheel Balancing Weights

Problem Statement

Manual Inspection of Wheel Balance Weights

Problem of Mixing with NG Parts

Manual Packing

Solution Delivered

Built Special Purpose Machine for wheel Balancing Weights Inspection

- Installed Two Vision Cameras for Both Side Inspection

- Developed Auto Marking on OK Components and Auto Rejection for NG components

- Built Automatic Packing and Sealing Machine

- Built QR Code Generation as per Customer’s Requirements

Productivity Increased by 15% | Process Time Reduced by 15% | Accuracy Increased to 95%

Industry : Automobile

Automatic Assembly of Pressure Control Valve (PCV) with Servo Press, EoL & Laser Marking Machine

Problem Statement

To Build a New Product Assembly Line to Meet Customer Demand

Solution Delivered

Built Special Purpose Machine for a Valve Assembly

- Built Servo Based Transfer System with Horizontal and Vertical Movement

- Built Servo Press for Caulking Operation

- Installed Vision Camera for Inspection

- Built EoL for Testing Final Assembly

- Installed Laser Marking Machine on Final Component

- Developed Traceability and IoT Application

Productivity Increased by 15% | Process Time Reduced by 15% | Accuracy Increased to 95%

Industry : Abrasive

Pick & Place with Vision Camera

Problem Statement

Missing Washer

Missing / Wrong Poly Mesh

Solution Delivered

Built Vibrator Feeder for Bush Feeding

- Built Pick and Place System

- Built Automatic Poly Mesh Placing

- Installed Vision Camera for Inspection

- Installed Vision Camera for Checking Presence and Confirmation of Poly Mesh and Washer

Quality Increases 99%

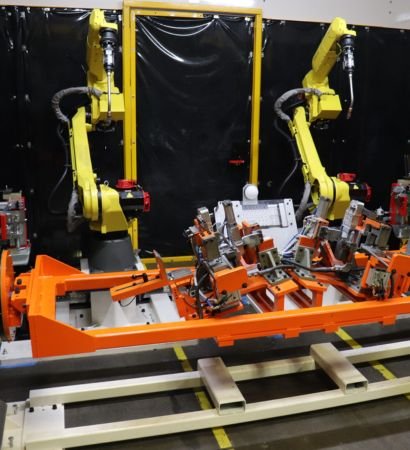

Industry : Automobile

Robotic Welding Cell

Problem Statement

Manual Welding was done Resulting in Low Productivity

- Quality Problem due to Non Repeatability of Welding Process

Solution Delivered

Built Special Purpose Machine

- Built Robotic Welding Cell with Two Welding Fixtures

Productivity Increased by 35% | Process Time Reduced by 40% | Accuracy Increased to 96%

Industry : Automobile

Automatic Shocker Assembly

Problem Statement

Manual Assembly of Shockers

- 12 Operators for 12 Different Operations

Solution Delivered

Built a Rotary Indexer Assembly Station

- Built Automatic Stations for Different Process

- Built Automatic Feeders for Each and Every Process to Feed Components into Indexer’s Station

- Developed SCADA for Operation Selection and Reporting

Productivity Increased by 35% | Process Time Reduced by 40% | Accuracy Increased from 96% to 99%